Equipment Finder

End-User License Agreement

The SmartPLAN® tool seamlessly manages both the operator’s and drilling contractor’s workflows to deliver digital drilling recipes that optimize efficiency and improve performance.

Key Features

- Enables digitalization of the operator’s and drilling contractor’s workflows

- Step-by-step driller instructions are presented on an intuitive user interface

- The recipe manager incorporates drilling recipes that are configured to reflect industry-wide best practices

- Integrates seamlessly with automation tools like SmartDRILL® and SmartSLIDE® to trigger automation

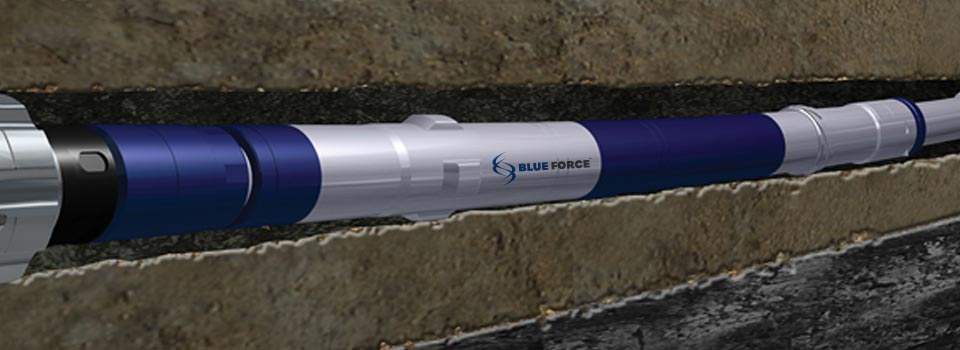

Blue Force® LWD DeepView®

Nabors offers the FracView® high-resolution LWD imager in 4.75 and 6.5 in collar sizes covering borehole diameter ranges from 5.875 to 9.5 inches. FracView was the first commercially available LWD borehole imager demonstrated to operate in long horizontal wells drilled with oil-based mud.

Key Features

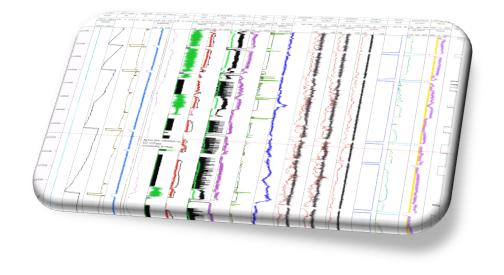

- DeepView Log Viewer capable of viewing and analysis of large volume high resolution drilling dynamics and imaging data in both time and depth domain

- Autonomous operation on any BHA and in any mud

- Suitable for Along String Measurement applications

- Compact 5 ft. long tools

- Economical service delivery

- Battery power and memory for >200 hrs of logging time

Predictive Drilling

Enhance ROP and minimize drilling dysfunction with Predictive Drilling. Control auto driller set points remotely using cloud based connectivity.

Key Features

- Enables remote control of rig site Auto Driller setpoints through a seamless cloud-to-cloud connection, without the need for any additional rig devices

- Bring substantial cost reductions per foot of drilling to your operations through increases in average ROP and decreases in vibration, mitigating drilling dysfunction

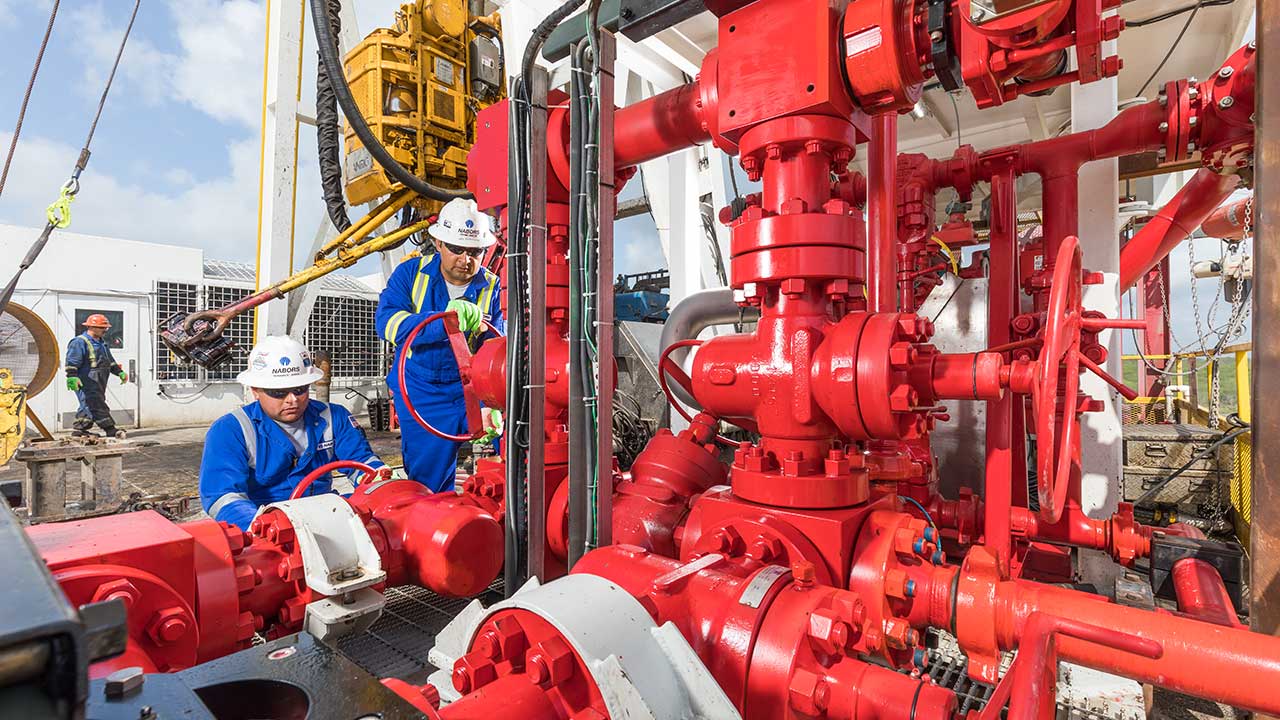

Integra™ Managed Pressure Drilling

Nabors’ fit-for-purpose managed pressure drilling (MPD) equipment and integrated MPD-Ready® drilling rig maximizes efficiencies and makes MPD services more scalable and cost-effective for unconventional land drillers.

Key Features

- Unique automated workflows eliminates the need for pre-job surveys and engineering, and minimizes high mobilization and rig-up costs.

- Elminates need for third-party service provider

- Increased safety, lower cost, reduced pad footprint

Blue Force® LWD DrillView®

Nabors offers the FracView® high-resolution LWD imager in 4.75 and 6.5 in collar sizes covering borehole diameter ranges from 5.875 to 9.5 inches. FracView was the first commercially available LWD borehole imager demonstrated to operate in long horizontal wells drilled with oil-based mud.

Key Features

- DeepView Log Viewer capable of viewing and analysis of large volume high resolution drilling dynamics and imaging data in both time and depth domain

- Autonomous operation on any BHA and in any mud

- Suitable for Along String Measurement applications

- Compact 5 ft. long tools

- Economical service delivery

- Battery power and memory for >200 hrs of logging time

Blue Force® LWD SpectraView™

Nabors offers the SpectraView™ LWD spectral/azimuthal gamma ray tools capable of covering borehole sizes from 5.875 to 9.5 inches. The tool measures and records naturally occurring gamma radiation from surrounding formations during wellbore drilling.

Key Features

- Sourceless gain stabilization/compensation

- API calibrated

- User-configurable azimuthal binning

- 80 Mbps ethernet readout protocol

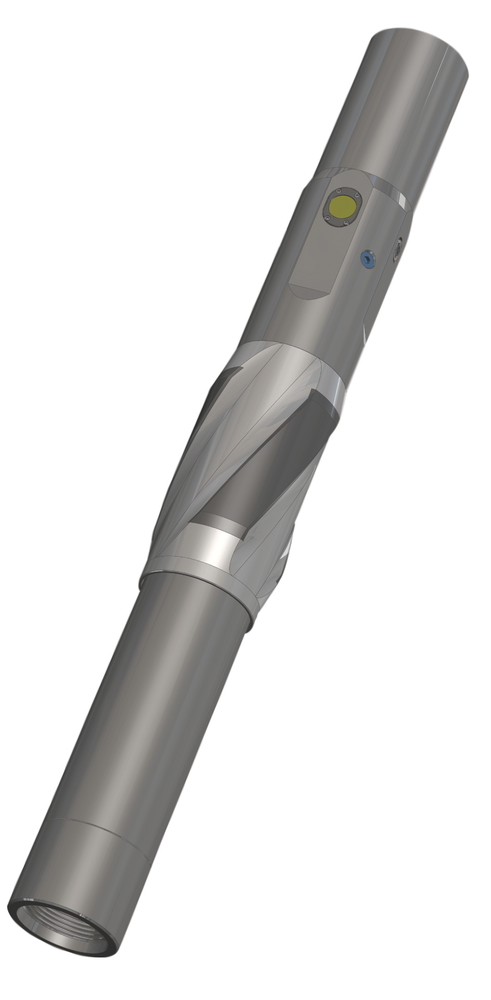

Blue Force® LWD FracView®

Nabors offers the FracView® high-resolution LWD imager in 4.75 and 6.5 in collar sizes covering borehole diameter ranges from 5.875 to 9.5 inches. FracView was the first commercially available LWD borehole imager demonstrated to operate in long horizontal wells drilled with oil-based mud.

Key Features

- Two independent transducers

- 360 degrees of coverage when rotating

- Autonomous operation

- Includes directional sensor for high side detection

- Battery power and memory for 200 hrs of logging time

- Fast readout via 80 Mbps port

- Screw-on stabilizers for wide range of borehole sizes

Blue Force® MWD Pulse

The AccuMP® MWD system differentiates itself from the competition by offering a variety of measurements to support single-station and multi-station analysis, including continuous inclination, real-time shock and vibration monitoring, gamma ray measurements, temperature readings and high-resolution surveys with real-time vector transmission. All measurements can be downloaded in high-resolution format for additional analysis and redundancy of data.

Key Features

- Robust electronics design and packaging to significantly reduce shock and vibration-related failures

- High-resolution data storage available for post drilling analysis

- Continuous inclination for enhanced positional awareness that eliminates check shots and results in a smoother wellbore

- Shock and vibration that mitigate hazardous drilling conditions before problems occur

- Smart telemetry for optimized rotating and sliding sequences for steerability and data logging

- Collar-mount design with no wellsite assembly required

- 24-hour monitoring from a remote center for redundancy and to ensure service quality

Blue Force® Motors

Nabors’ Blue Force® mud motors are customized to specific specifications, built to withstand all drilling fluid types and temperatures, and can help reduce non-productive time.

Key Features

- Mud-lubricated bearing design – not affected by mud type or temperature

- Multiple power section configurations available to suit a variety of drilling environments

- Vertical drilling motors are available that can be configured for any hole size

Cementing & Casing Accessories

Nabors offers cementing and casing accessories, including hydroform centralizers, Multi-Lobe Torque™ (MLT®) rings, reaming shoes and cementing solutions.

Key Features

Read more

Deepwater Casing

Nabors offers conventional casing running services for running large OD tubular to heavy lift tubular.

Offshore Completions

Nabors offers conventional and proprietary tubular running services for running offshore drilling tubulars with or without control lines.

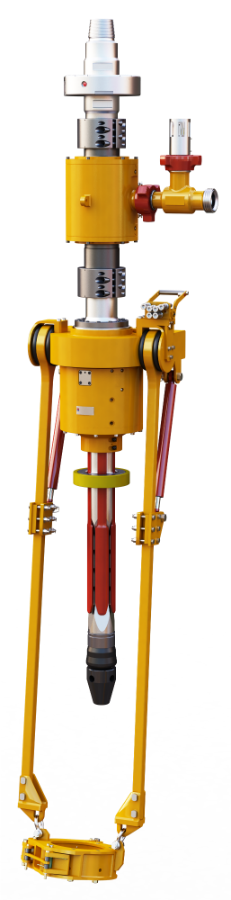

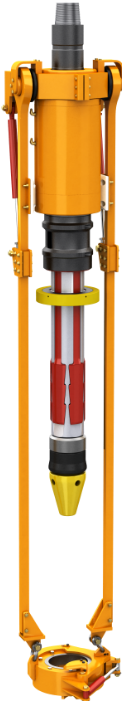

Onshore Automated Casing Running

Nabors’ automated tubular service technology brings significant improvements in safety, performance, reliability and efficiency during casing drilling and tubular running operations.

Key Features

- Increased automation and equipment is needed for casing running operations

- Reduces liability and increases the efficiency and safety of operations

Onshore Casing Running

Onshore tubular services and solutions include casing running, tubing running, torque monitoring, pick-up and laydown technology, remotely operated tubular solutions and installation of control lines.

Key Features

- Variety of solutions including casing and tubing running, torque monitoring, and remotely operated tubular solutions

- Ability to run basic to complex well completions

- Safe and Efficient

SmartPLAN®

The SmartPLAN® tool seamlessly manages both the operator’s and drilling contractor’s workflows to deliver digital drilling recipes that optimize efficiency and improve performance.

Key Features

- Enables digitalization of the operator’s and drilling contractor’s workflows

- Step-by-step driller instructions are presented on an intuitive user interface

- The recipe manager incorporates drilling recipes that are configured to reflect industry-wide best practices

- Integrates seamlessly with automation tools like SmartDRILL® and SmartSLIDE® to trigger automation

SmartDRILL®

Proprietary automated drilling activity sequencer that optimizes rig processes. Proven to consistently improve connection times, increase one run laterals and decrease unplanned trips, the SmartDRILL™ system drives scalable cost reduction and improved drilling performance. Workflows are digitalized to improve procedural adherence and ensure that best practices are being configured for future wells.

Key Features

- Engineered sequences automate drilling practices safely and efficiently

- Optimized rig processes reduce downhole equipment damage and unplanned trips

- Best practices are digitalized to produce repeatable results

- Fully integrated with the SmartNAV™ and SmartSLIDE™ systems to enhance performance

- Expanded functionality and performance measurement through integration with RigCLOUD®

SmartROS® Rig Operating System

Nabors SmartROS® automates many repetitive drilling tasks while integrating data from both downhole tools and surface systems. Automating these functions allows the driller to follow the customer’s well plan with a higher level of precision and operational excellence.

Key Features

- Activity-based workflows

- Intuitive, icon-based navigation screens

- Integration of smart features on a single interface, operators can leverage the features of SmartNAV®, SmartSLIDE®, SmartDRILL®, RSS downlinking and ROCKit®

- Automation framework that supports a novel recipe manager that can be triggered by planned depths using the SmartPLAN® system

- Standard on Nabors rigs, but can be installed on any rig domestically or internationally regardless of manufacturer

REVit® Technology

Nabors REVit® technology features advanced top drive automation that eliminates stick slip, a common mode of vibration that limits drilling performance.

Key Features

- Advanced top drive automation that provides real-time stick slip mitigation

- Monitored service to ensure the correct use of the system

- An upgrade to the top drive for effectiveness that does not diminish throughout the run

ROCKit® System

The ROCKit® Suite significantly increases rate of penetration (ROP) by rocking pipe and delivering ideal weight to bit. It promotes improved toolface control by allowing fine adjustments while still drilling ahead, reducing the need for lubricants and other friction-reducing additives. Drillers save time by quickly setting toolface orientation.

Key Features

- Overcome low ROP when sliding by allowing the directional driller to oscillate the drill pipe left and right while slide drilling

- Slow toolface setting time through a patented quill position that enables the driller to quickly orient the toolface prior to sliding

- Steer corrections while slide drilling from the control panel

Remote Control Chokes

Nabors offers remote control choke technology to help operators meet the challenges of well pressure control, while reducing costs and enhancing environmental risk and wellsite safety.

Key Features

- Nabors chokes can be tied into existing rig control systems and functions displayed in the driller’s cabin

- Managed pressure drilling can be integrated into the control system

- Rotating heads can be monitored for pressure and wear

Variable Bore Rams

This integrated offering includes variable bore rams (VBRs), which consists of two rams on the blow-out preventer (BOP) that extend to the center of the wellbore. During well control events, VBRs can be used to shut the well in.

Key Features

- Designed to fit the desired drilling application

- Superior rig efficiency and reliability

Rotating Control Devices

This integrated offering includes rotating control devices (RCDs) for the onshore unconventional market. RCDs are utilized for pressure management during drilling for the purpose of making a seal around the drillstring while the drillstring rotates.

Key Features

- Eliminates the need to source multiple third-party vendors with differing service quality and/or safety standards

- Efficient and reliable

BOP Testing

Nabors provides BOP installation and inspection as well as API-compliant, field-proven testing of BOP components in compliance with industry standards.

Key Features

- Safety features, such as isolation and pressure relief valves

- User-friendly control panel

- Test results captured in a digital format, ensuring the integrity of test results and access to an electronic file for future reference

Non-Stop Driller™

Non-Stop Driller™ is a sub-based constant circulation system that allows the continuous circulation of drill fluids downhole while making or breaking drill pipe connections, enabling improved wellbore stability and hole cleaning, reduced risks of influx and optimum drilling performance.

Key Features

- Enhanced cleaning and continuous solids transport

- Provides seamless integration to UBD/MPD operations, offering unprecedented bottom-hole pressure control on connections

- Eliminates post-connection stabilization time during multiphase drilling on air, foam and two-phase wells

SmartSLIDE® Automated Slide Drilling

The SmartSLIDE™ system integrates critical downhole information needed for directional drilling and then automatically implements corrective instructions and steering logic during slide drilling operations.

Key Features

- Configurable directional steering control system

- Visualization and analysis tools of the planned and as-drilled trajectory

- Fully integrated with the SmartNAV™ directional guidance software and the SmartDRILL™ machine task sequencer

- Customized service through operations experts to facilitate training, remote support and KPI monitoring to ensure operational performance

- Expanded functionality and performance measurement through integration with RigCLOUD®

SmartNAV® Directional Guidance System

Nabors’ SmartNAV® platform is an automated directional drilling decision-making system that visualizes the downhole positions of the drill bit and the planned well path and automatically generates instructions to keep the well on course.

Key Features

- Visualization and analysis tools of the planned and as-drilled trajectory

- Facilitates collaboration between users at the rig or in a remote operating center

- Interactive slide or rotate steering instructions provided on a stand-by-stand basis

- Customizable rules, best practices and steering tolerances

- Expanded functionality through integration with RigCLOUD®